On July 9th, a team of leading experts from the China Machine Tool Builders Association visited our company for a special inspection and research. The inspection focused on the 14th Five-Year Plan for the development of high-end equipment manufacturing, engaging in in-depth discussions on key topics such as technological breakthroughs, industrial applications, and the development of industry standards for five-axis CNC machine tools.

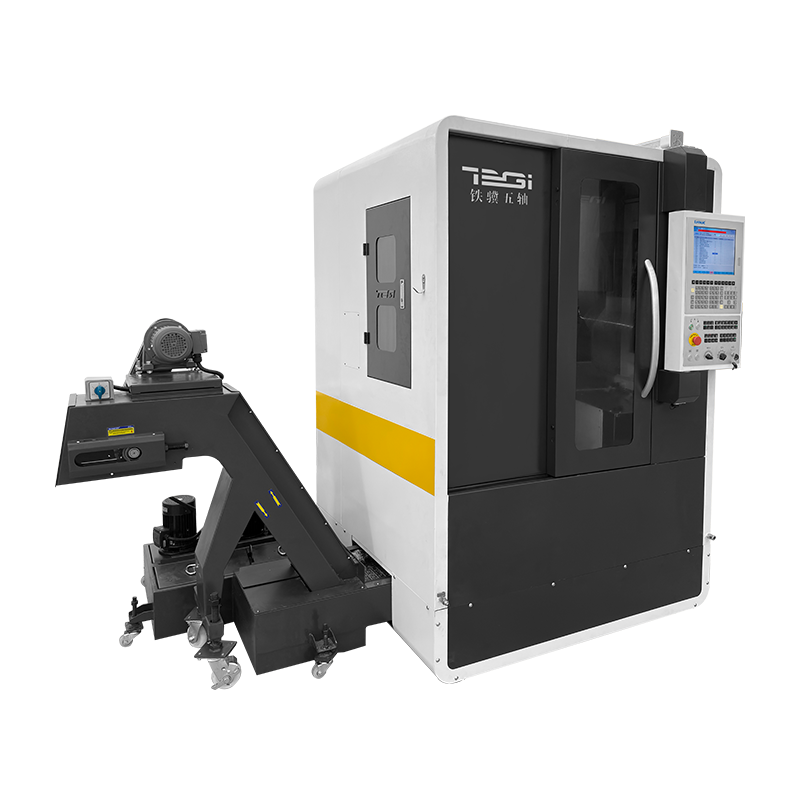

[On-site Inspection] During the three-hour on-site visit, the delegation toured three core areas of our company: the intelligent production workshop for five-axis machining centers, the precision assembly line for key functional components, and the national-level testing center. In the precision manufacturing workshop, which maintains a constant temperature and humidity, the association's technical experts observed a live demonstration of our newly developed G-series five-axis machining center. The machine's 0.003mm repeatability and intelligent thermal compensation system sparked heated discussion. The head of the quality management department detailed the seven patented technologies of our independently developed CNC system, including multi-axis synchronous control and vibration suppression.

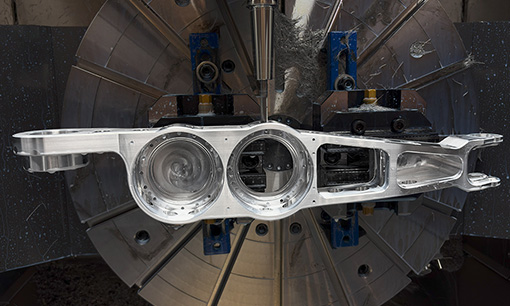

[Technical Discussion] At the symposium, representatives of the company's technical committee systematically reported on three major breakthroughs achieved in recent years: first, they mastered key technologies for maintaining precision in five-axis machine tools, enabling the equipment to maintain positioning accuracy within 0.005mm after 2,000 hours of continuous operation; second, they developed a specialized process package for aircraft engine blade machining, increasing machining efficiency by 40%; and third, they established an intelligent operations and maintenance platform based on the Industrial Internet, achieving a 92% accuracy rate for equipment failure warnings. Experts from the association's Standardization Working Committee specifically noted that "these innovative practices provide important reference examples for industry technological upgrades."

[Industrial Collaboration] The two sides reached several strategic consensuses: first, establishing a quarterly technical exchange meeting mechanism to share cutting-edge R&D developments; second, jointly conducting key component research projects such as "high-precision CNC rotary tables"; and third, jointly participating in the development of international standards. In their summary, the association's leaders emphasized, "We look forward to the company continuing to leverage its strengths in 'specialization, precision, uniqueness, and innovation' to set an industry benchmark in improving the reliability and intelligent transformation of high-end CNC machine tools."

This visit has laid a solid foundation for deepening industry collaboration. The company will use this opportunity to accelerate the research and development of core technologies and their industrial application.

Record number:

Record number: