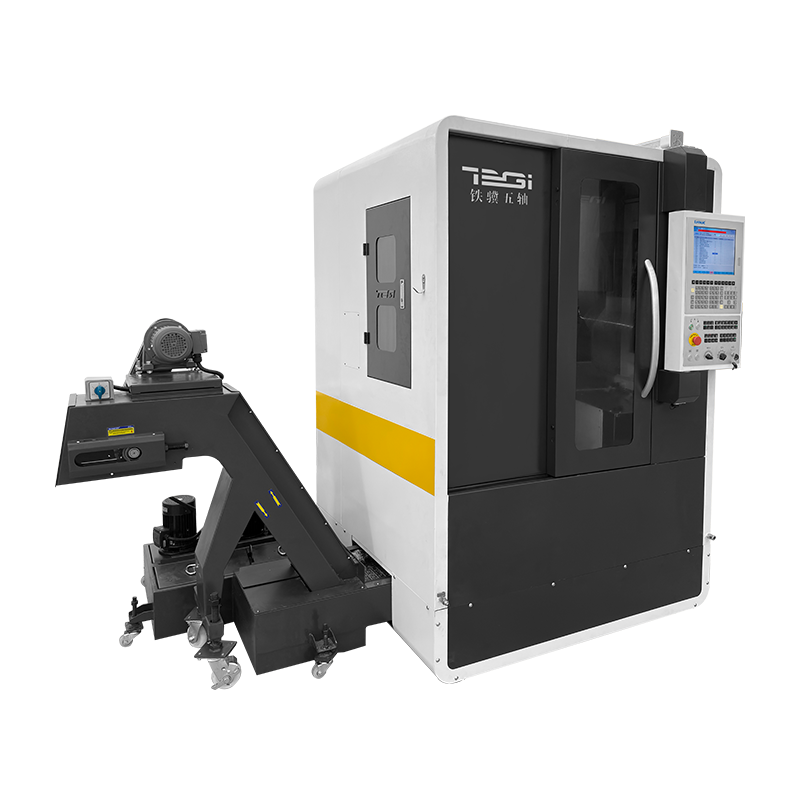

| Project | Specification | Unit |

| Processing range | Workbench diameter | ∅1,000 | mm |

| The maximum rotational diameter of the workpiece | ∅1,200 | mm |

| The countertop is lower than the A-axis | 100 | mm |

| The maximum height of the workpiece (including fixtures) | 900 | mm |

| The maximum weight of the workpiece and fixture | 2000 | kg |

| Feed shaft | X/Y/Z axis travel | 1,000/1,200/800 | mm |

| A-axis stroke | -280 | ° |

| C-axis travel | N*360 | ° |

| The distance from the end face of the spindle to the worktable | 180-980 | mm |

| Maximum speed along the X/Y/Z axis | 72 | m/min |

| Rated speed of A/C axis | 30/50 | rpm |

| Maximum torque of the A/C axis | 12,000/6,000 | Nm |

| Main shaft | Spindle tool holder interface | HSK-A100 |

|

| Maximum rotational speed of the main shaft | 12000 | rpm |

| The spindle torque is S1/S6-25% | 300/510 | Nm |

| Tool magazine | Tool magazine capacity | 36[72] | T |

| Maximum tool diameter/length | 125/425 | mm |

| Maximum tool weight | 30 | kg |

| Tool change time | 10 | s |

| Precision | Closed-loop control of X/Y/Z axes | Standard |

|

| A/C closed-loop control | Standard |

|

| The positioning accuracy of the X/Y/Z axes is ISO 10791-4:1998 | 0.005 | mm |

| The positioning accuracy of the A/C axis is ISO 10791-4:1998 | 5 | Arc seconds |

| Repeat positioning accuracy of X/Y/Z axes ISO 10791-4:1998 | 0.003 | mm |

| Repeat positioning accuracy of A/C axis ISO 10791-4:1998 | 3 | Arc seconds |

| The external dimensions of the main machine part (length/width/height) (front machine tool) | 3,000/5,000/3,200 | mm |

| Machine tool weight (excluding accessories) | 30000 | kg |

| Total electrical capacity | 80 | KVA |

Record number:

Record number: